Two major reasons workers experience eye injuries on the job are because they were:

1. Not wearing eye protection, or

2. Wearing the wrong kind of protection for the job.

Personal protective eyewear, such as goggles, face shields, safety glasses, or full face respirators must be used when an eye hazard exists. The eye protection chosen for specific work situations depends upon the type of hazard, the circumstances of exposure, other protective equipment used, and individual vision needs.

What are the potential eye hazards at work?

Potential eye hazards against which protection is needed in the workplace are:

Projectiles (dust, concrete, metal, wood and other particles)

Chemicals (splashes and fumes)

Radiation (especially visible light, ultraviolet radiation, heat or infrared radiation, and lasers)

Blood borne pathogens (hepatitis or HIV) from blood and body fluids.

Some working conditions include multiple eye hazards. The proper eye protection takes all hazards into account.

The best methods of eye protection differ for each type of hazard. The protector must be matched to the potential hazard.

High risk occupations for eye injuries include:

Construction

Manufacturing

Mining

Carpentry

Auto repair

Electrical work

Plumbing

Welding

Maintenance

The type of safety eye protection you should wear depends on the hazards in your workplace:

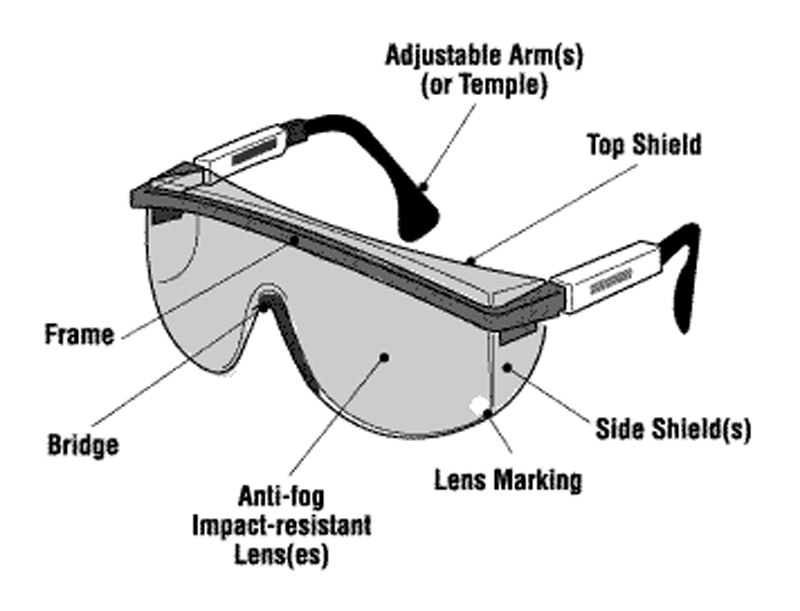

If you are working in an area that has particles, flying objects, or dust, you must at least wear safety glasses with side protection (side shields)

If you are working with chemicals, you must wear goggles

If you are working near hazardous radiation (welding, lasers, or fiber optics) you must use special-purpose safety glasses, goggles, face shields, or helmets designed for that task.

In addition, employers need to take steps to make the work environment as safe as possible. This includes:

Conducting an eye hazard assessment of the workplace

Removing or reducing eye hazards where possible

Providing appropriate safety eyewear and requiring employees to wear it

How can I protect my eyes from injury?

There are four things you can do to protect your eyes from injury:

1. Know the eye safety dangers at your work.

2. Eliminate hazards before starting work by using machine guards, work screens or other engineering controls.

3. Use proper eye protection.

4. Keep your safety eyewear in good condition and have it replaced if it becomes damaged.

Selection of protective eyewear appropriate for a given task should be made based on a hazard assessment of each activity.

Types of eye protection include:

Non-prescription and prescription safety glasses — Although safety glasses may look like normal dress eyewear, they are designed to provide significantly more eye protection. They have lenses and frames that are much stronger than regular eyeglasses. Safety glasses must meet standards of the American National Standards Institute (ANSI). Look for the Z87 mark on the lens or frame.

Safety glasses provide eye protection for general working conditions where there may be dust, chips or flying particles. Additional side protection can be provided by the use of side shields and wraparound-style safety glasses.

Safety lenses are available in glass, plastic, polycarbonate and Trivex™ materials. While all four types must meet or exceed the minimum requirements for protecting your eyes, polycarbonate lenses provide the highest level of protection from impact.

The shield provided by goggles protects eyes from chemical splashes and ocular exposure to bloodborne pathogens.

Goggles — Goggles provide impact, dust and chemical splash protection. Like safety glasses, safety goggles are highly impact resistant. In addition, they provide a secure shield around the entire eye and protect against hazards coming from any direction.

Goggles can be worn over prescription glasses and contact lenses to provide protection from flying objects and chemical splashes and in dusty environments.

Face shields and helmets — Full face shields are used to protect workers exposed to chemicals, heat, or blood borne pathogens. Helmets are used for welding or working with molten materials. Face shields and helmets should not be used as the sole means of protective eyewear. They need to be used in conjunction with safety glasses or goggles. Wearing safety glasses or goggles under face shields also provides protection when the shield is lifted.

Special protection — Other types of protection, such as helmets or goggles with special filters to protect the eyes from optical radiation exposure, should be used for tasks such as welding or working with lasers.

One way to ensure that safety glasses provide adequate protection is to be sure they fit properly. Also, eye protection devices must be properly maintained. Scratched and dirty devices reduce vision, cause glare and may contribute to accidents.

Protective eyewear works best when you know how to use it properly. Combined with machine guards, screened or divided work stations, and other engineering controls, using the correct protective eyewear can help keep you safe from any type of eye hazard.

Seek medical attention as soon as possible following an injury, particularly if you have pain in the eye, blurred vision, loss of vision or loss of field of vision.